Our Custom Service

Highlights of Our Capabilities for Your Project

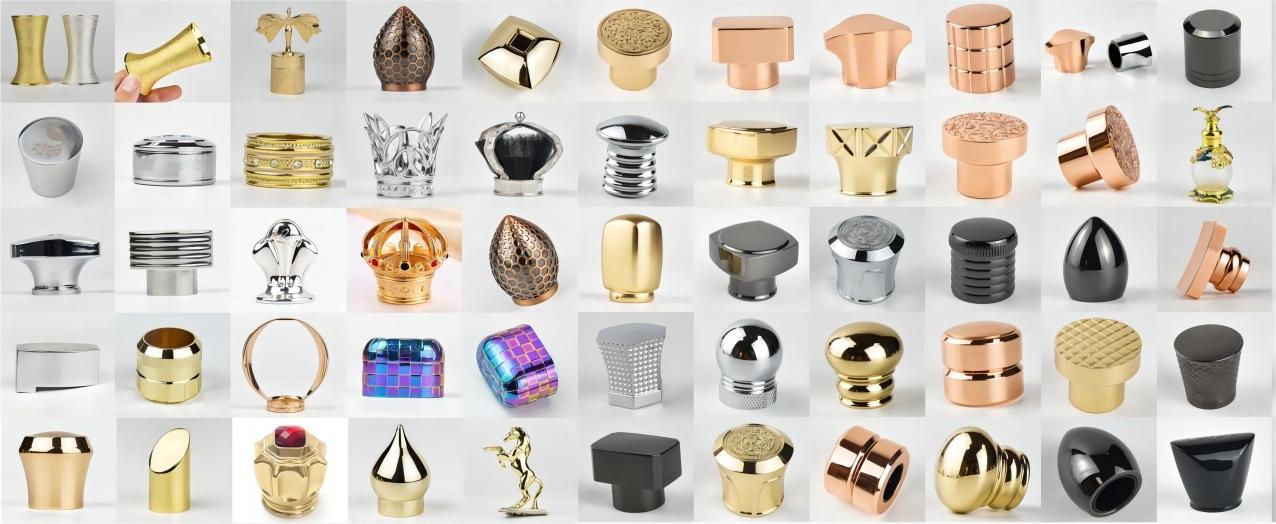

Please allow me to make a simple introduction. We are the hardware accessories manufacturer and good at handling various intricate post-processing on zamak to come true your designs for mass production. Besides custom zamak caps, we have a partner glass bottle factory to work together, which is fully qualified to assist in the development of your entire perfume bottle set.

Why choose us?

At iPackagePro, we can offer one-stop solutions that integrate zamak expertise with glass bottle manufacturing, ensuring seamless coordination in high-quality for your projects.

We have senior engineers specialized in the full set design of perfume bottles. They can support you from hand-drawn sketches to structural engineering drawings. This is a paid service, ranging from 350USD to 500USD per design. The price includes a 3D mock-up for 7 days. The time for a crystal mock-up will be slightly longer and 300USD to 350USD as extra cost.

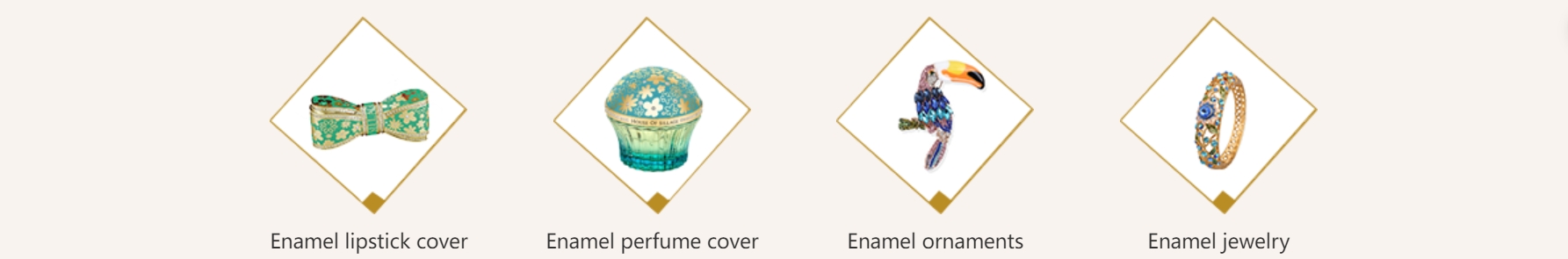

Engineering structure and complex post-processes are our strengths. Mr. Dong, a senior engineer with over 30 years of experience in luxury jewlery and hardware cosmetic packaging industry, be available quickly respond to solutions regarding structural optimization, materials, processesing techniques during product development for mass production preparation. Our product categories include metal perfume caps, solid perfume compact, metal lipstick tubes, metal cosmetic mirrors, etc. We can achieve luxury packaging requests with our exquisite epoxy/enamel craftsmanship or galvanized plating/painting/PVD coating/watertransfer/hotstamp/UV printing/silkprinting/padprinting to reach your shiny or matte finish.

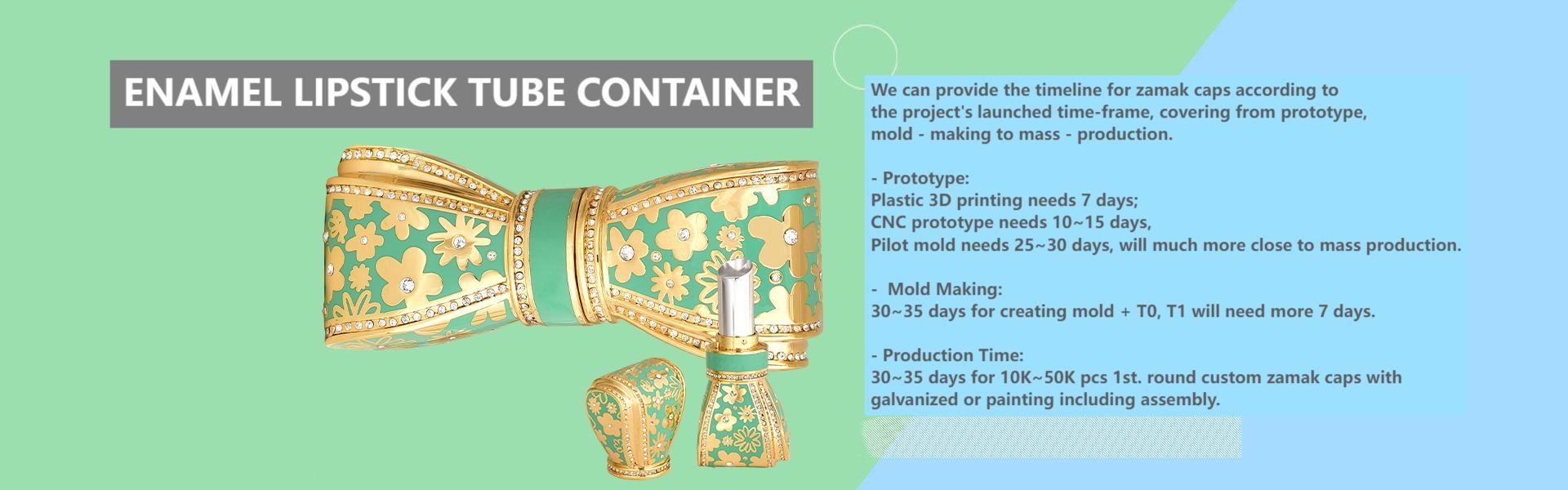

We can provide the timeline for zamak caps according to the project's launched time - frame, covering from prototype, mold - making to mass - production.

Prototype: Plastic 3D printing needs 7 days;

Crystal Mockup or CNC prototype needs 10~15 days,

Trial/Pilot Mold needs 25~30 days, will much more close to mass production.

Mold Making: 30~35 days for creating mold + T0, T1 will need more 7 days.

Production Time: 40~45 days for 10~50K pcs 1st. round custom zamak caps with galvanized or painting including assembly.

-- Ready to Create Your New Fragrance&Cosmetic Packaging Project? Contact Us Today!

Website: www.ipackagepro.com | www.zamakpro.com

Email: [email protected]

Phone: +86-13433099901 (WhatsApp/WeChat)

⬇️

The Ultimate Guide to Purchasing Custom Zamak Cosmetic Packaging & Accessories Solutions to Elevate Your Fragrance&Cosmetic Brands : OEM & ODM & NDP Turnkey Support

The Ultimate Guide to Purchasing Custom Zamak Cosmetic Packaging & Accessories Solutions to Elevate Your Fragrance&Cosmetic Brands : OEM & ODM & NDP Turnkey Support

Hand-enameled Process

Hand-enameled Process

Quality Control

Quality Control